Back-painted Glass

Backpainted glass has several characteristics that make it an excellent material for a variety of interior applications where beauty and functionality are critical. One of the most common applications is using backpainted glass for kitchen backsplashes which provides clean seamless surface for easy cleaning and maintenance. GlassWise’s state-of-the-art processing and customization capabilities allow for the fabrication necessary for custom projects of any size in both commercial and residential applications.

The color options are endless as we offer custom color matching and you can also choose the surface finish to be gloss or satin etched finish if you’re looking to add texture to a specific area.

Printed Glass

Digitally printed glass is made by using a digital file of an image, pattern or a symbol/logo which is printed onto the surface of the glass. The ink used is ceramic and is then thermally cured which makes it difficult (if not impossible) to damage. The ceramic ink comes in an assortment of colors depending on the colors in the digital file provided. Your imagination is the limit to what you can create!

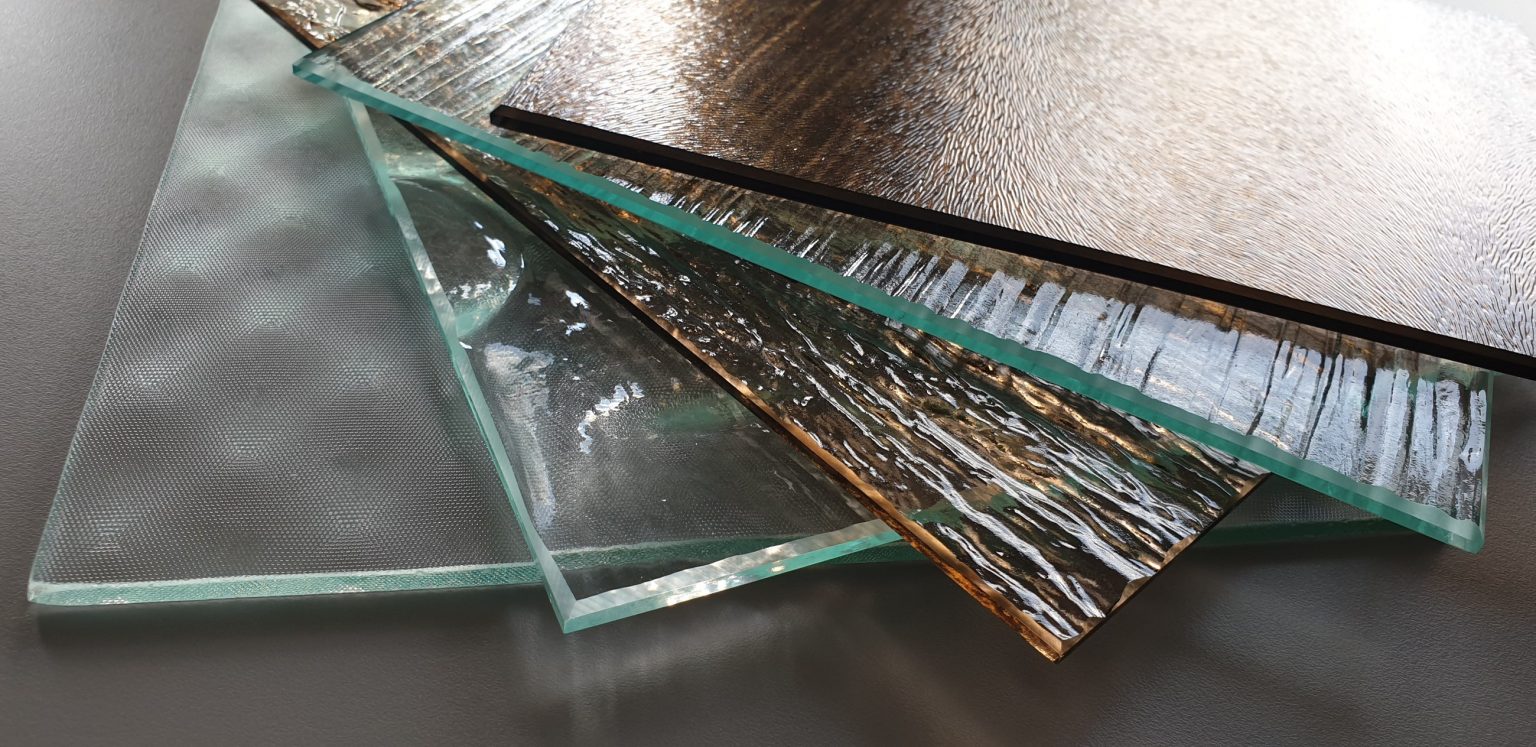

Textured Glass

Textured glass is available in a range of designs and it is typically made by placing a regular smooth surface sheet of glass over a textured mould and heated at very high temperatures to form the intended shape. The most common textured glass used designs are the reed-like textures, horizontal or vertical lines, sometimes in rain textures or in bubbles.

Using textured glass will provide better privacy while getting the optimum use of daylight and a stylish interior difficult to find anywhere else.

FAQ

How long does it take to complete a project ?

Installation times vary from the time we measure your opening to the day we install the glass. There are a number of circumstances that come into play. For example, if you have a custom printed glass enclosure, it takes about 3-4 weeks just to fabricate your glass. Etching on glass can increase lead times as well as the glass need to be fabricated, laid out for the etching design, and then the etching process begins. Typically, we install most shower doors within 2 weeks once the opening has been field measured.

What needs to be completed before you can measure?

How long will it take for you to measure and what can I expect?

It will take one to two hours to fully measure a typical glass enclosure. Our measurement technicians use special equipment to get exact measurements, which will then be used in our CAD software to get an accurate final quote.